Electrolytic Mold Cleaning Machine

ELIOS

Standard type electrolytic ultrasonic cleaner recommended for mold cleaning!

What Does Electrolytic Cleaning Mean?

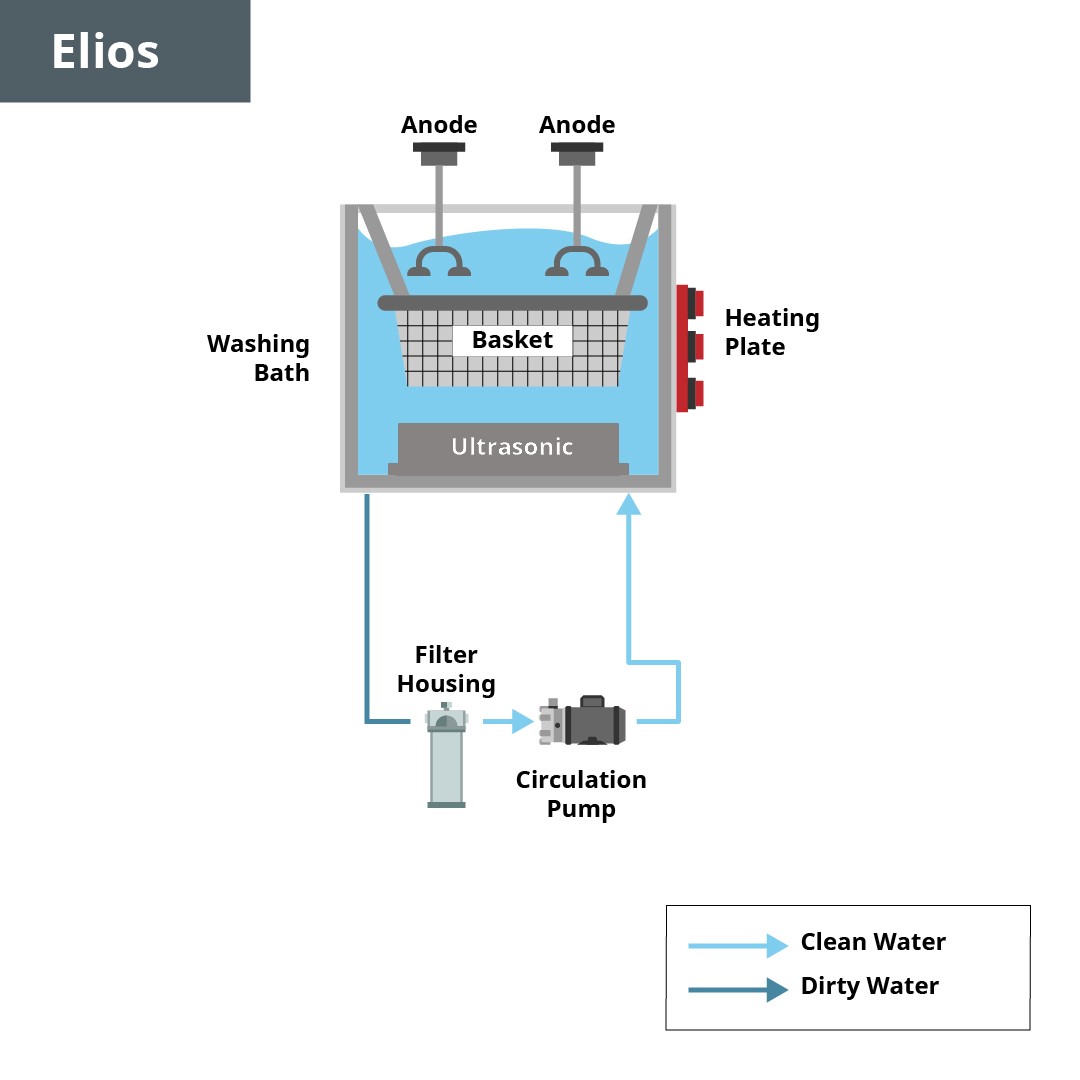

Electrolytic cleaning is a method of removing dirt from a metal surface by subjecting it as an electrode to an electric current in an electrolytic bath. It is a form of electroplating that can be applied to all electric conductive materials

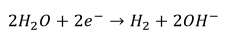

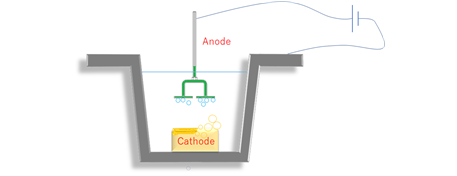

a DC current is applied between an undissolved electrode and the workpiece to be cleaned. Cathodic reactions are applied for this system which the workpiece is made the cathode and a reduction reaction occurs at the surface.

Hydrogen generates during the reaction produce a scrubbing effect on the surface of part and peel off the dirt on workpiece, as cleaning parts.

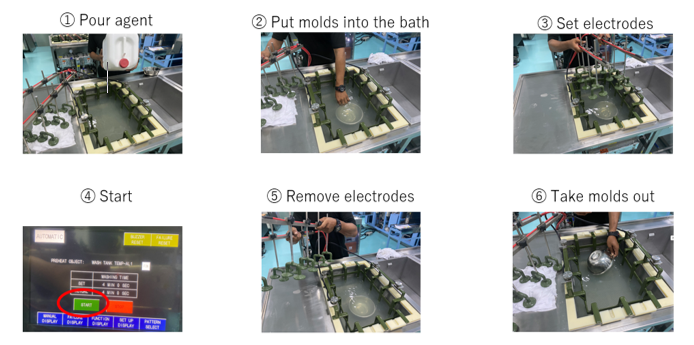

Cleaning Mechanism

- Set the anode electrode after immersing the mold into the cleaning bath

- The mold attaches to the basket which made the cathode

- Hydrogen gas is generated between the mold and the dirt part with energization

- Gas lifts dirt and peels off dirt with ultrasonic cavitation

- Dirt surfaces up to the liquid surface with gas and is removed with a filter

Advantages

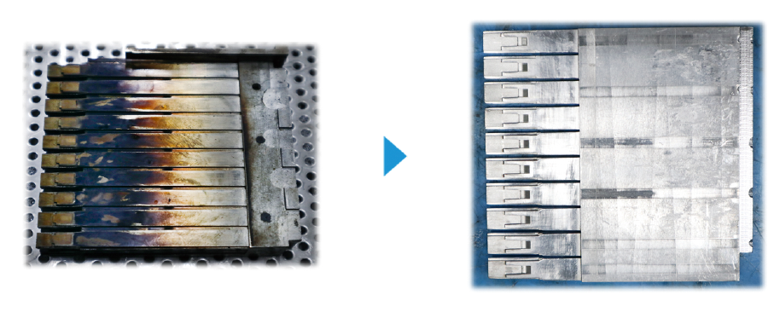

- Manual maintenance tends to cause scratches, but this machine does not cause any scratches and less clean uniformly.

- Removes dirt from uneven areas that cannot be reached with brushes

- Heating type improves cleaning performance

- Reduction of molding defect rate and increase the lifespan of molds

- No toxic gas is emitted

Standard Specifications

| Lineup | ELIOS-4030 | ELIOS-6040 | ELIOS-8050 |

| Basket Size WxDxH (mm) | 400x300x200 | 600x400x350 | 800x500x500 |

| Bath Volume | 65L | 115L | 375L |

| Ultrasonic | 40kHz 1000W | 40kHz 2000W | 40kHz 3000W |

| Heater | 500W x 2 | 500W x 2 | 500W x 4 |

| Filtration pump | 100W (30L/min) | 194W (60L/min) | 194W (60L/min) |

| DC | 15V, 50A | 15V, 80A | 15V, 120A |

| Dimension | 1110x840x1300 | 1400x1000x1660 | 1870x1120x1800 |

| Weight | 250kg | 400kg | 600kg |